Order today and get a free consultation on your model!

Order today and get a free consultation on your model!

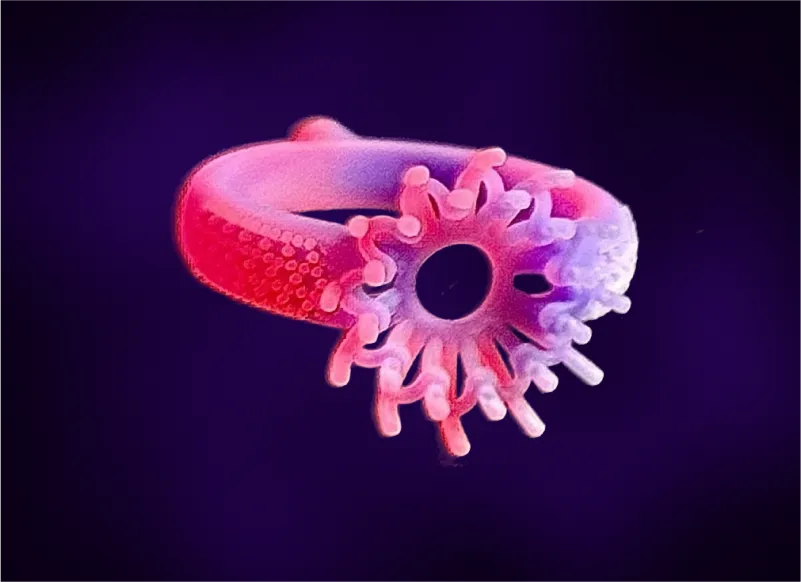

Create jewellery with jewellery precision – we turn 3D ideas into waxes ready for casting. High quality, perfect detail and speed – everything a true craftsman needs.

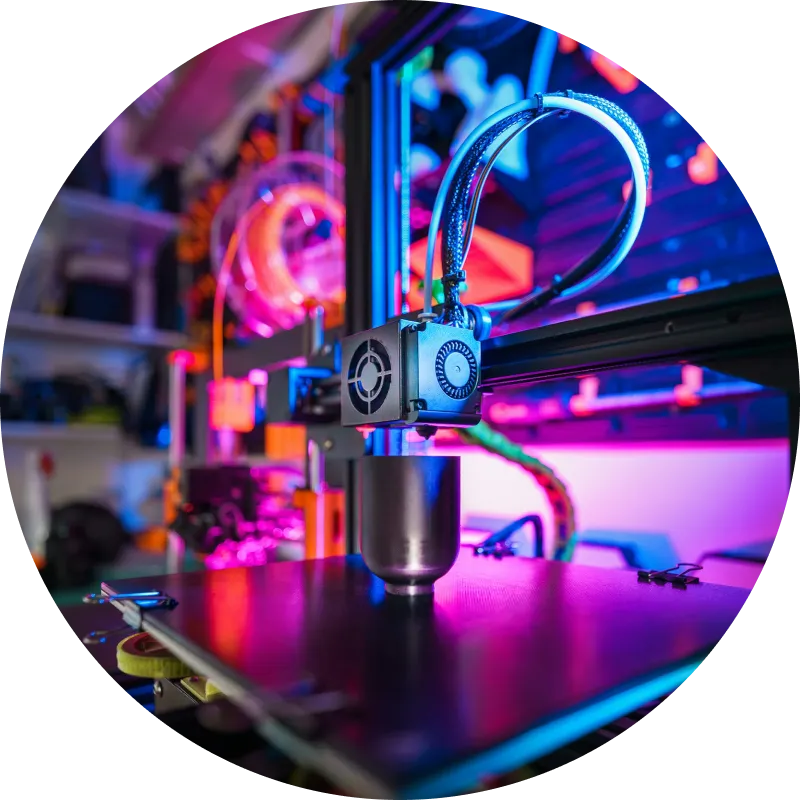

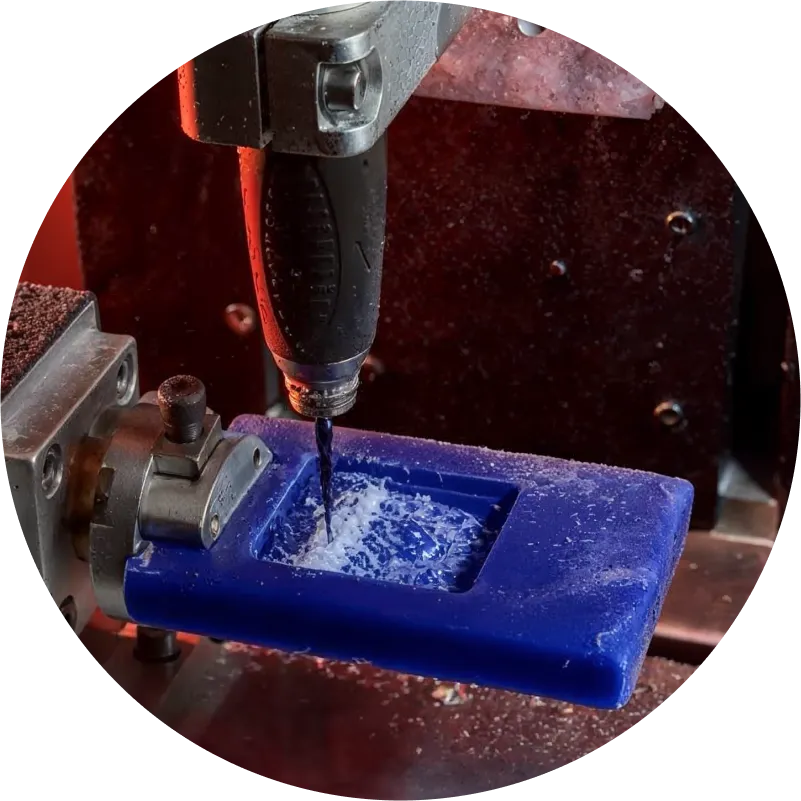

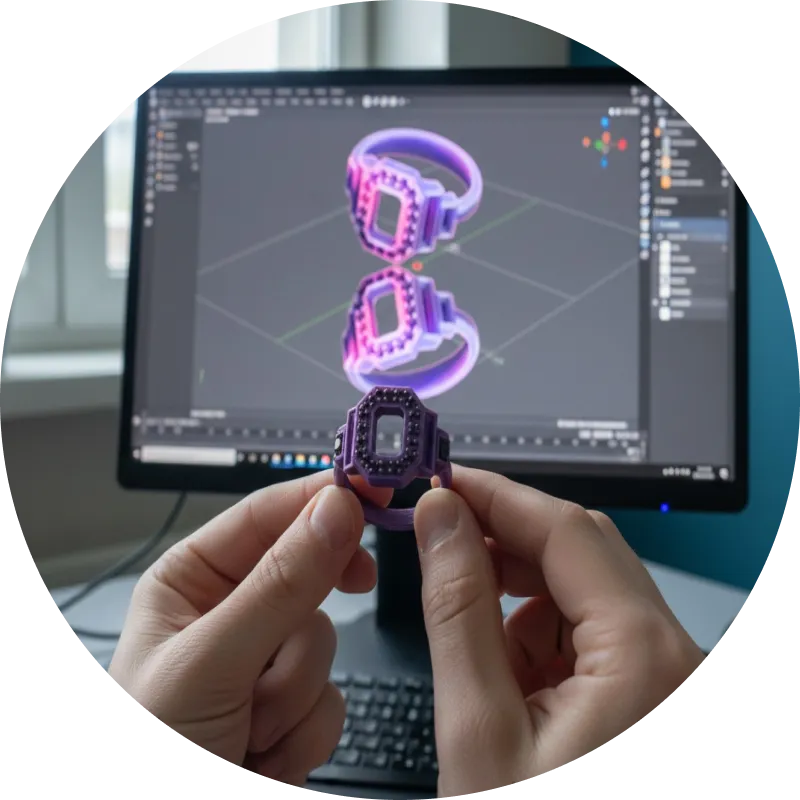

Modern jewellery production is impossible without precise and reliable equipment. We use the latest 3D printing and machining technologiesto make each model as close as possible to the customer's idea. Everything we create goes through digital precision and engineering logic – from design to final waxing. Our arsenal includes advanced solutions that ensure consistent quality and the highest level of detail in our models:

hat create waxes with perfect precision

suitable for complex geometry and deep reliefs

to ensure accurate preparation of the layout for casting

which guarantees quality control at every stage of production

This allows us to produce wax models of jewellery that do not require modification and are fully ready for use. Our equipment is not just a technique, but a tool that turns an idea into a mould and a sketch into a ready-made basis for jewellery. That is why 3D Vision waxes are chosen by those for whom stability, precision and results are important.

Thanks to this technical base, we confidently undertake projects of any complexity – from the finest filigree elements to massive moulds with deep elaboration of relief. Our technologies allow us to achieve repeatability even in the smallest details, which is especially important for serial production of jewellery.

Each stage – from 3D modelling to printing – is automated and controlled by experienced specialists. This allows us not only to speed up production time, but also to eliminate the risk of defects. We don't just produce waxes – we create tools that will make your jewellery precise, elegant and durable.

We at 3D Vision are convinced: that a good wax is not just a casting blank, but the foundation of a future piece of jewellery. That is why we approach each order with attention to detail and strict quality control. Our models are characterised by perfect shape, clean surface and exact compliance with all requirements.

High precision, so our products are ideal for complex shapes and delicate elements.

Smooth surface without defects, minimising post-processing time.

Optimal wax composition that burns out easily without cracking or warping.

Fully compatible with foundry technology – suitable for both customised and serial production.

Guaranteed conformity to specification – no surprises at the final stage.

Thanks to this approach our jewellery waxes become the choice of professionals all over Ukraine. We are confident in the result, because each model undergoes a final check before dispatch.

See for yourself – go to the catalogue and choose the shape that will perfectly fit your jewellery.

Each wax model is created taking into account the real conditions of casting and the wishes of the master. We take into account the peculiarities of wall thickness, shape, possible kinks and minimum radii. This individual approach allows us to achieve the ideal result from the first casting – without corrections, delays and unnecessary costs.

Our customers are jewellers, designers and foundries, for whom not only technical performance is important, but also confidence in the result. With 3D Vision, you get a partner who understands the industry, can work to tight deadlines and always takes into account individual requirements. We value our reputation, so we keep quality first, regardless of the size of the order.

Even in the most non-standard tasks, we offer optimal solutions: we adapt the model to the casting, suggest how to strengthen the structure, or offer an alternative approach. This is our difference – we don't just create waxes, we accompany your project from idea to casting, helping you to achieve a perfect result.

Замовте ювелірні моделі в 3D Vision і переконайтеся в бездоганній якості вже з першого виробу.

We use proven equipment and high precision CNC machines that provide better accuracy. This allows us to create complex shapes with perfect detail and excellent quality.

Our waxes burn out easily, do not crack or deform during moulding. They have a smooth surface and are fully conformed to the drawings without the need for modification.

Each model is visually and digitally inspected for geometry, surface finish and compliance with all requirements. We do not send any part without a final check.

Yes, we work with individual projects: you can send us a 3D model or even a hand-drawn sketch. Our specialists will help you to bring your idea to the finished wax.

The catalogue of models and current prices are available online on the website. You can choose the desired option and immediately place an order in a few clicks.

A standard order takes from 1 to 5 working days to fulfil. We can process urgent projects on a priority basis.